Reducing Capex and delivering LCOE benefits to Offshore Wind Farms

Background

The tremendous growth in both speed of delivery and scale of Offshore Wind Farms has driven the cable industry to develop new solutions for higher power cable ratings, even in the most onerous installation conditions.

The pace of development in both Alternating Current (AC) and Direct Current (DC) subsea cables in the last decade is unparalleled in the history of the cable industry with three core Cross Linked Polyethylene Cable (XLPE) cables now possible at up to 275kV with 2500sqmm conductors and HVDC XLPE single core cables developed at up to 640kV with 3000sqmm conductors.

The design of the cable and the installation conditions define the cable thermal performance limitations for this new generation of cable systems. Integrated optical fibres coupled with real time thermal rating systems for continuous in-service temperature sensing have identified that cable systems are operating at much lower temperatures than anticipated based on steady state thermal rating calculations conducted during project design phases. Advances in accuracy of in service diagnostics has created a need for more accurate cable thermal ratings to be conducted.

The Challenge

Whilst Distributed Temperature Sensing (DTS) systems provide peace of mind for in service operation, the design optimisation of cable systems at feasibility and front end engineering design (FEED) project phase remains challenging. Cable systems are traditionally sized based on steady state thermal rating and industry standard algorithms defined in International Electrotechnical Standard (IEC) 60287 for power cable systems. This assumes that the cable operates at full load with a conductor temperature at the maximum permissible level for the lifespan of the cable system.

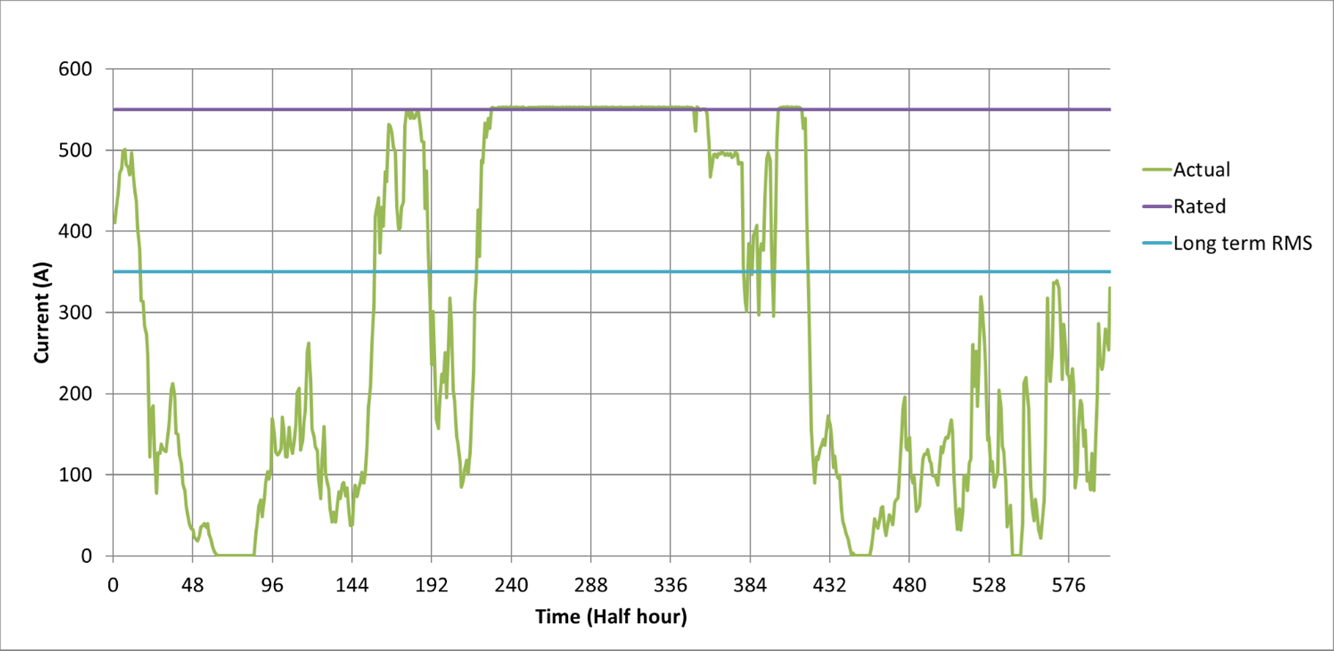

Steady state thermal rating therefore delivers a conservative thermal rating that fails to optimise the cable asset over its service life often limiting the potential power transmission. It is estimated that long term root mean square (RMS) current is only at 50 to 75% of the full load rating of offshore wind farm export cable (Figure 1). In addition, the IEC algorithms do not take into consideration the time taken to heat the thermal mass of the installed environment assuming instead a worst case scenario of steady state temperature.

The pressure on developers to deliver competitive Levelised Cost of Energy (LCOE) values for offshore wind projects has created a focus on maximising the potential of wind resources as well as the cable infrastructure required to deliver the generated power to the grid. There is an industry need to bridge the gap between conservative steady state ratings and dynamic in-service thermal ratings, monitored in real time.

The Solution

In response to the industry need, ITPEnergised developed a series of tools to address the need to model the thermal performance of cables in-service more accurately. These dynamic rating tools have progressed in complexity.

Solution 1: Single Step Dynamic Rating

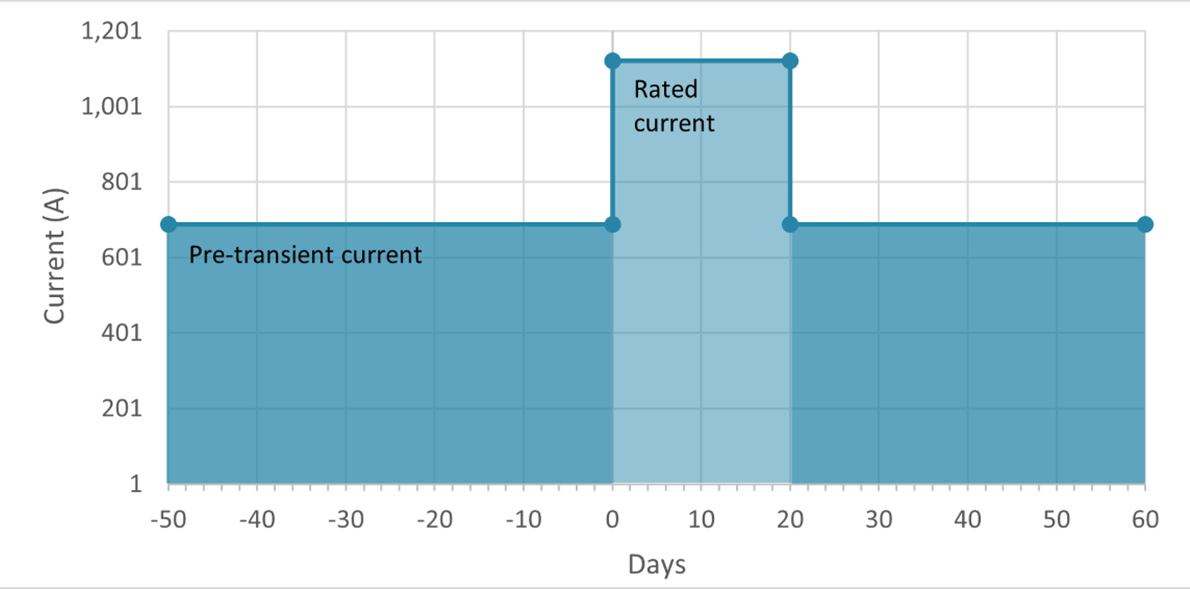

A single step transient rating based on the general requirements of IEC60287 (Steady state ratings) and IEC60853 defining a calculation method for considering emergency and cyclic ratings and modelling the impact of a single worst case wind event on cable thermal performance.

This method was deployed on an offshore wind project in Asia where the application resulted in a reduction of export cables from five AC circuits to four circuits and a saving of USD 20 million to the project.

Solution 2: Multiple Step Dynamic Rating

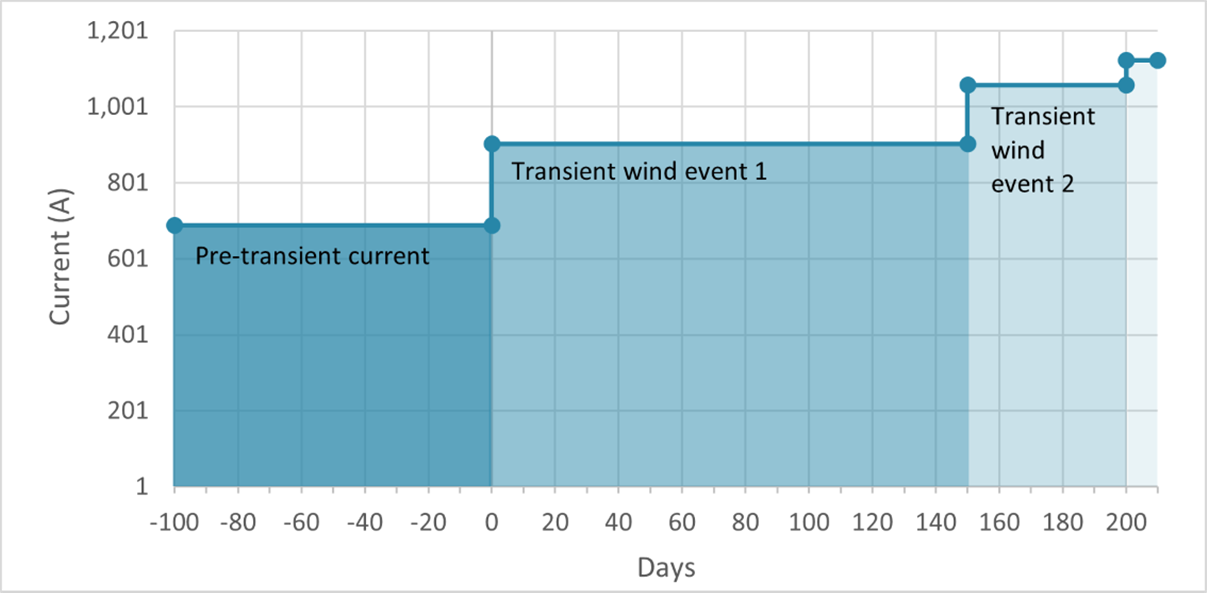

Based on the principles outlined in IEC 60853 and IEC 60287 with a more complex multi-step approach. This method considered the impact of successive major wind events modelled concurrently on cable thermal performance (transient wind event 1 and 2 on graph).

This method was successfully deployed on a European Offshore Wind Farm feasibility study where the steady state rating resulted in a curtailment from required 400MW rating to 310MW due primarily to a thermally challenging landfall. The use of the multi-step rating method delivered the required rating of 400MW with a reduction in cable size from the originally evaluated 220kV three core 2000sqmm cable to an 1800sqmm conductor cross sectional area. This not only resolved the curtailment on the project but also delivered a 10% saving on cable system cost excluding installation cost savings associated with smaller, lighter cables.

Solution 3: Time Series Dynamic

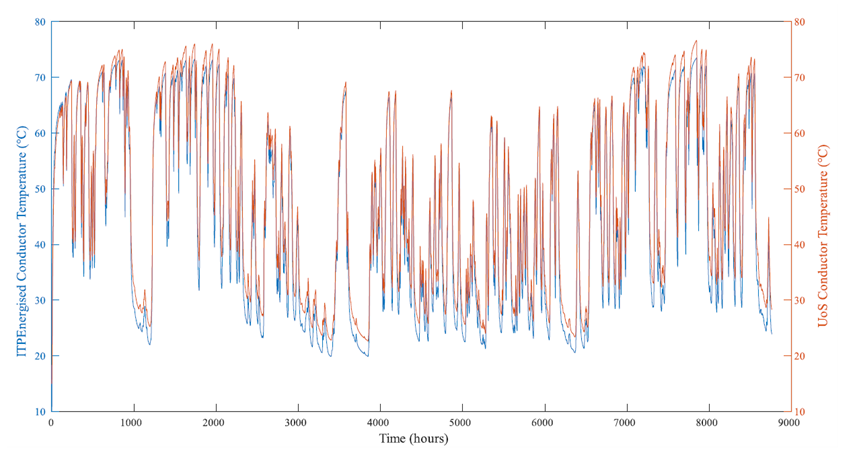

A step change in methodology using IEC 60287 and IEC 60853 as the foundation of the technique together with research undertaken by leading industry experts, ITPEnergised developed a tool that models the thermal performance of cables in service over the system life using hindcast wind data to reflect real life operational parameters.

The tool was used in a recent project in the United Kingdom to model the cable thermal performance of an export cable system using 12 months of wind data taken at hourly intervals. This iterative but conventional calculation developed a thermal profile of the cable and demonstrated a GBP 28.7 Million saving for a 100km long export cable system (cable cost only) through the downsizing of cable conductor when compared with original steady state rating solution.

Summary

- Steady state ratings significantly under-utilise export cable systems

- Dynamic ratings are possible for offshore wind projects due to time varying cable current and the slow thermal response of buried cables

- There are no internationally accepted standards for dynamic ratings although research is on-going at CIGRE.

- Dynamic rating can provide significant capital savings on export cable savings delivering benefits to LCOE calculations

- Calculations can be ratified in service using Real Time Thermal Rating systems (DTS)

Download a PDF of the Dynamic Thermal Ratings for Subsea Cable Systems case study here.

For more information on this cost-reducing and unique service at ITPEnergised, contact: Brian Branney, Head of Technology +44 (0)7379 940 564, brian.branney@itpenergised.com